Testing and Research

Event Horizon can offer the complete engineering package. Working closely with the client at each step of the research programme design process enables us to supply a final product that delivers with immediate effect. Starting with CAD and finite element simulations, initial designs are carried through to our versatile workshops for fabrication and testing.

Maintaining a full in-house machine shop allows us to provide a full engineering solution, ranging from welding and fabrication to CNC machining. Our specialisations include design of hydraulic and pneumatic control systems and software.

An extensive range of testing covering UN series, STANAG and EMTAP is available alongside bespoke impact testing.

Event Horizon is a registered firearms dealer (RFD: 52/3181) and hold Home Office Section 5 Authority.

For a full list of capabilities, please see our capabilities page or view our capabilities PDF: Capabilities PDF

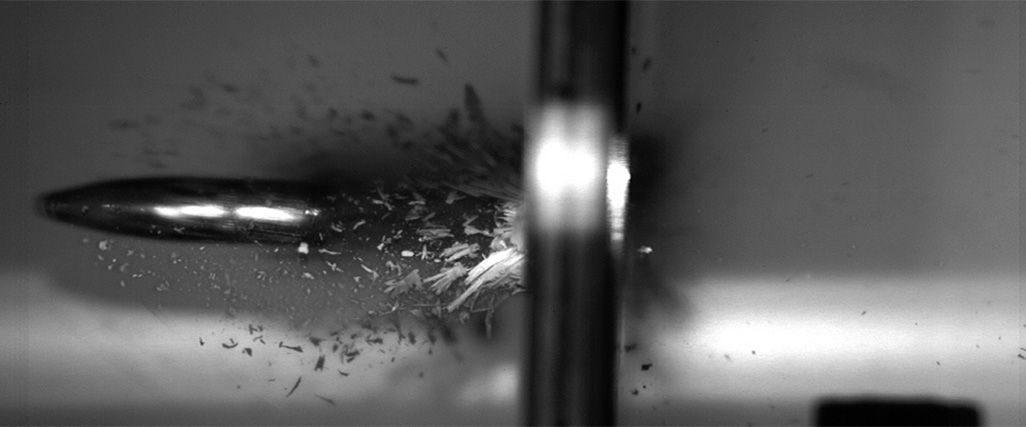

Impact Testing

Event Horizon design and operate a range of Impact Test Systems. We have various single stage and a two-stage reservoir light gas gun system. Our single stage systems have the capability to fire a range of hard and soft body projectiles, including:

• Ball bearings for FOD assessment (various barrels from 6mm to 75mm diameter).

• Ice hailstone sphere (25 and 50mm spheres).

• Hardbody metallic projectiles (axi-symmetric and irregular with option of various keyed barrels).

• Gelatin, bird, and slurry projectiles.

Our two-stage light gas gun is pneumatically driven and incorporates a modular design allowing interchangeable first and second stage barrels for varied configurations. Demonstrated speed of 1400m/s with a 30gram / 20mm diameter projectile with a bespoke air-strip sabot assembly. Design capability with a hardbody at 30mm bore is 1800m/s, with capacity for hypervelocity speeds at reduced bore sizes.

Capability exists to condition specimens on test from -60°C to 1100°C at the point of impact. Using our in-house design and manufacturing capability we can also provide bespoke test fixtures and sabot systems.

Event Horizon owns a range of high-speed cameras, including: iX-717; and Vision Research T2410 cameras. These cameras are capable of shooting 24,270 fps at 1280 x 800 and upto 2,450,000fps at 280x12. Data logging can be provided using our DEWESoft SIRIUS-HS STG modules providing 1MHz data rate at 16 Bit resolution, these modules can be configured to record a wide variety of inputs.

Testing and Evaluation

We have the ability to undertake a range of UN, EMTAP and STANAG tests including:

UN:

• Test Series 1 (a) - Gap Test (Zero Gap)

• Test Series 2 (a) - Gap Test (50mm Gap)

• Test Series 3 - BAM drop hammer, BAM friction and Thermal Stability

• Test Series 4 - Thermal Stability Test, 12 Meter Drop Test

• Test Series 5 - External Bonfire Test

• Test Series 6 - Single Package Test, Stack test, External Fire Test, Unconfined Package Test

EMTAP:

• Test 4 - Ease of Ignition (Bickford Fuze) Test

• Test 5 - Train Test

• Test 6 - Electric Spark Test

• Test 7 - Electric Spark Test For Sensitive Explosives

• Test 11 - Small Scale Gap Test

• Test 36 - Fragment Attack Test

• Test 40 - Shaped Charge Attack Test

• Test 41 - Tube Test - Fast Heating

• Test 42 - Tube Test - Electrically Heated

• Test 43 - BAM Impact Test

• Test 44 - BAM FRICTION TEST

STANAG:

• Bullet Attack

• Fragment Attack

• Slow Heating

Equipment:

• Gas Chromatography / Mass Spectrometry (GCMS) – Agilent 8890 GC & 5977 MS

• Unity XR Thermal Desorption (Markes International)

• Differential Scanning Calorimetry (DSC) - Mettler Toledo

• Scanning Electron Microscope with Electron Dispersive Spectrometer

• X-Ray

• Coulometric Karl Fischer Titrator - Mettler Toledo

Field Trials:

• Fragmentation Trials

• Blast wave pressure measurement in the near, mid and far field (PCB)

Further Testing:

• Capabilities for design and commission of specialist test facilities to suit customer requirements

Diagnostics and Analysis

We are able to offer and field an array of in-house specialist high speed recording and analysis equipment including:

• Multichannel high-speed data collection

• Near field blast pressure

• Optical chronographs

• High Temperature Thermocouple

• Ballistics Pressure measurements

• Sound pressure recording and logging

• Multichannel Accelerometers - Triaxial

• High speed digital video

Further diagnostics can be accommodated for specialist requirements.

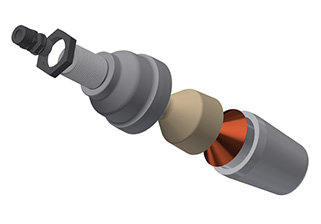

Charge Design

Event Horizon offer an end to end program for charge design: Initial CAD design inception through computer simulation and refinement to safety and function testing at our facilities.

After a design is finalised, a packaging solution can be designed, manufactured, tested and approved for transport to your requirements. Once delivered we offer qualified expert support to your ongoing trials.

Environmental Testing

Event Horizon design and operate a range of Environmental Testing Systems including:

• 1㎥ Diurnal Test Chamber (‐65 to +130°C)

• Data Physics Vibration Shaker Table

• Salt Mist Chamber

• Bounce Rig

• Sand and Dust

• Drop Rigs with Remote Release

• X‐Ray capability

• Environmental Test Equipment close coupled to Underground range for proofing and test purposes

• Environmental Test Capability to support Safe, Suitable, for Service (S3) programmes

Product Design and Development

Event Horizon have in‐house design, development and manufacture capabilities including:

• Bespoke Linear Cutting Charges

• Bespoke Conical Shaped Charges

• Pneumatic and Hydraulic Systems

• Rig Fixtures

• Ballistic Systems

• Small Scale Rockets

• Control Systems (Hardware and Software)

• Packaging Solutions

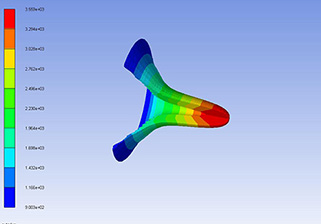

Simulation

Event Horizon have a variety of in‐house Simulation capabilities including:

• Shaped charge jet development and cutting performance

• Blast analysis

• Ballistic impact

• Fragmentation

• High strain rate component failure modes

• Gas compression and expansion

• Computational Fluid Dynamics (CFD)

• Structural Mechanics

© Event Horizon Ltd

The Old Brewery, Stagman Lane,

Ashcott, Somerset, TA7 9BJ, UK